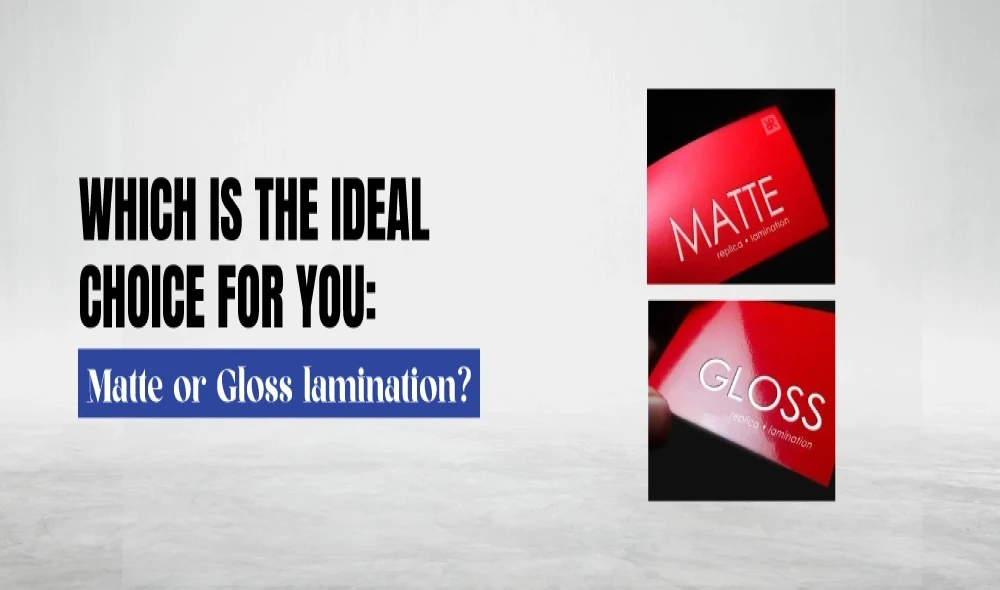

Which is the Ideal Choice for You: Matte or Gloss Lamination?

Lamination is a crucial finishing process when it comes to printing materials. It serves the dual purpose of protecting the printed surface and enhancing its visual appeal. By applying a thin plastic film, lamination safeguards the material against moisture, dust, and fingerprints. Additionally, it adds an extra layer of gloss or matte finish, making the material look more attractive and professional.

However, the decision between matte and gloss lamination can be quite challenging. Each type of lamination brings its own set of advantages and disadvantages. In this article, we will compare matte and gloss lamination to help you determine which one suits your specific needs.

Matte Lamination

Matte lamination is a finishing process that imparts a soft, dull, and non-reflective appearance to the printed material. It reduces glare, making text and images easier to read. Matte lamination is an excellent choice for materials that require a sophisticated and understated look. Here are some advantages of matte lamination:

- Minimal Glare: Matte lamination reduces glare and reflection on the printed material, ensuring readability.

- Subtle Look: Matte lamination offers a soft, non-reflective finish that is perfect for materials requiring a subtle and sophisticated appearance.

- Fingerprint Resistance: Matte lamination is more resistant to fingerprints and smudges, making it ideal for frequently handled materials.

- Durability: Matte lamination adds an extra layer of protection, making the printed material more durable and long-lasting.

However, there are a few disadvantages to consider:

- Color Reproduction: Matte lamination can dull the colors of the printed material, reducing vibrancy and contrast.

- Scratches: Matte lamination is more prone to scratches and scuffs, making it less suitable for materials subjected to heavy wear and tear.

- Cost: Matte lamination generally comes at a higher price point compared to gloss lamination.

Gloss Lamination

Gloss lamination, on the other hand, provides a shiny, reflective, and high-gloss finish to the printed material. It enhances colors and adds vibrancy, making the material visually appealing. Gloss lamination is an excellent choice for materials that require a vibrant and eye-catching look. Here are some advantages of gloss lamination:

- Vibrant Colors: Gloss lamination enhances colors, making them more vivid and eye-catching.

- Scratch Resistance: Gloss lamination offers better resistance to scratches, making it suitable for materials exposed to heavy wear and tear.

- Cost: Gloss lamination is generally more cost-effective compared to matte lamination.

However, there are a few downsides to consider:

- Glare: Gloss lamination reflects light, causing glare and potentially making text and images harder to read.

- Fingerprint Susceptibility: Gloss lamination is more prone to fingerprints and smudges, making it less suitable for materials frequently handled.

- Reflections: Gloss lamination can reflect the environment, creating unwanted reflections on the printed material.

Which One Should You Choose?

Ultimately, the choice between matte and gloss lamination depends on the specific needs of your project. If you require a sophisticated and subdued look with minimal glare and resistance to fingerprints, matte lamination may be the best option for you. On the other hand, if you desire vibrant colors, scratch resistance, and cost-effectiveness, gloss lamination may be more suitable.

Best Times to Use Matte and Gloss Lamination

Both matte and gloss lamination offer great finishing options for various printed materials. Here are some ideal scenarios to use each type:

Best Times to Use Matte Lamination

- Business Cards

- Book Covers

- Menus

- Brochures

Best Times to Use Gloss Lamination

- Posters

- Photographs

- Product Packaging

- Flyers